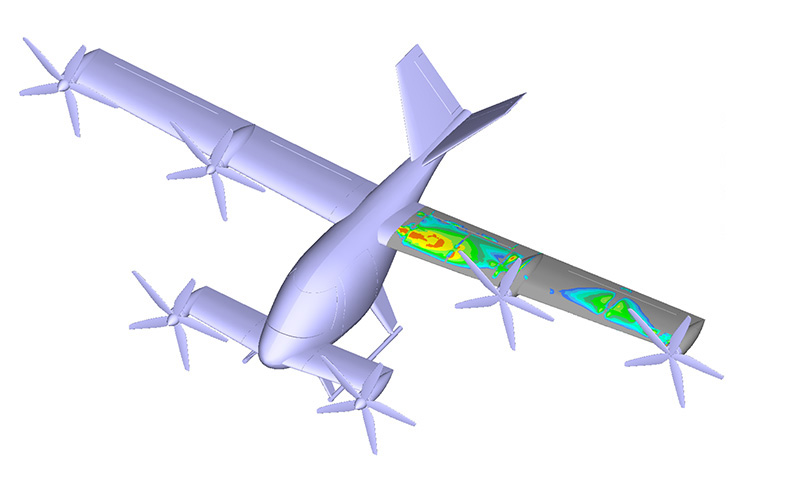

From conceptual design through prototyping and manufacturing, we provide comprehensive expertise in developing and analyzing aerospace structures and systems. Our capabilities cover both metallic and composite materials, delivering innovative and reliable solutions that meet the highest standards of performance and reliability. Our deep technical expertise in structural loads, static and dynamic analysis, and composite structures helps you solve complex engineering challenges with confidence delivering precise, validated results that reduce technical risk, support certification requirements, and keep your program on track at critical decision points.

We excel in aerospace structural conceptual design, laying the foundation for innovative, high-performance vehicles. Early in the process, we guide clients in exploring optimal structural configurations, material choices, and load paths tailored to mission goals, weight targets, and manufacturability. Utilizing advanced modeling and deep industry knowledge, we create designs that harmonize with aerodynamic and systems engineering, focusing on safety, efficiency, and lifecycle cost to ensure a smooth transition from concept to detailed design.

Our detail design approach emphasizes precision, performance, and manufacturability. Integrating advanced simulations with expertise in aerospace materials and processes, we optimize both primary structures, such as fuselage frames and wing spars, for strength-to-weight and safety, and secondary structures, such as brackets and fairings, for durability and cost-effectiveness. Collaborative and cross-disciplinary, we develop designs that integrate seamlessly into airframe assemblies, supporting innovation and certification readiness.

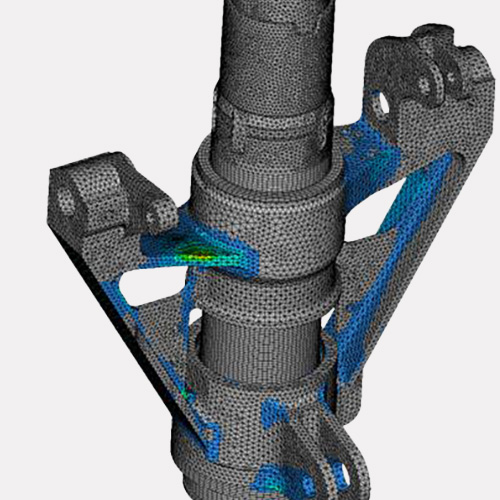

Approaching assembly design with a systems-level perspective, we balance structural performance, integration, and producibility. By thoroughly analyzing load paths, interface requirements, and environmental factors, we ensure assemblies meet integrity and certification criteria. Prioritizing modularity and precision alignment, we streamline installation and maintenance to reduce lifecycle costs. Close collaboration with our cross-functional teams optimizes designs for manufacturing feasibility and supply chain efficiency, resulting in durable, adaptable assemblies that perform reliably throughout service life.

Our structural loads analysis encompasses a thorough evaluation of aerodynamic, inertial, and dynamic forces across full flight envelopes and mission scenarios. Developing detailed load cases reflecting real-world conditions, we integrate loads into a unified analytical framework to ensure structural components withstand operational demands safely and efficiently.

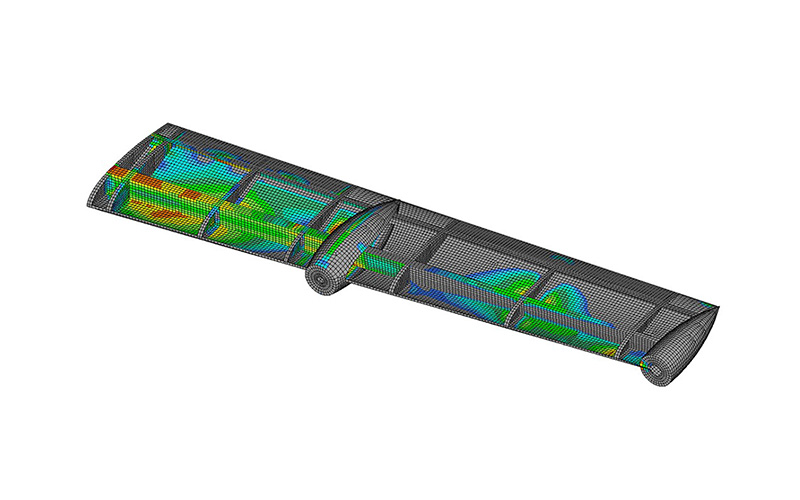

We combine classical theories with advanced computational methods for comprehensive static and dynamic structural analysis. Classical techniques provide fast, reliable baselines for critical load paths, while finite element modeling (FEM) tackles complex geometries and nonlinear behaviors with precision. Dynamic analyses capture transient responses to impacts and oscillations through modal, harmonic, and time-history methods. Cross-validating classical and FEM results ensures accuracy and supports design iterations from early studies through certification.

With deep expertise in composite structures, we apply specialized FEM tools to model material behavior and optimize performance through detailed ply definition. Our experience spans high-performance wing skins with bonded assemblies, space structures spanning thermal regimes, and both low end and high-end material systems where we incorporate manufacturing experience considering fiber orientation, residual stress, and cure effects. Our practical design and analysis approaches ensure project specific structural fidelity and supports certification and innovation while utilizing lightweight solutions.

Let’s Build the Future of Aerospace Together

Re:Build Answer Engineering is prepared to be your partner to ensure your project is designed and analyzed with precision, performance, and safety. Whether you’re in the early stages of conceptual design or preparing for structural testing, our team is standing by to support your goals with proven expertise. Contact us today to learn how we can help bring your program to life.