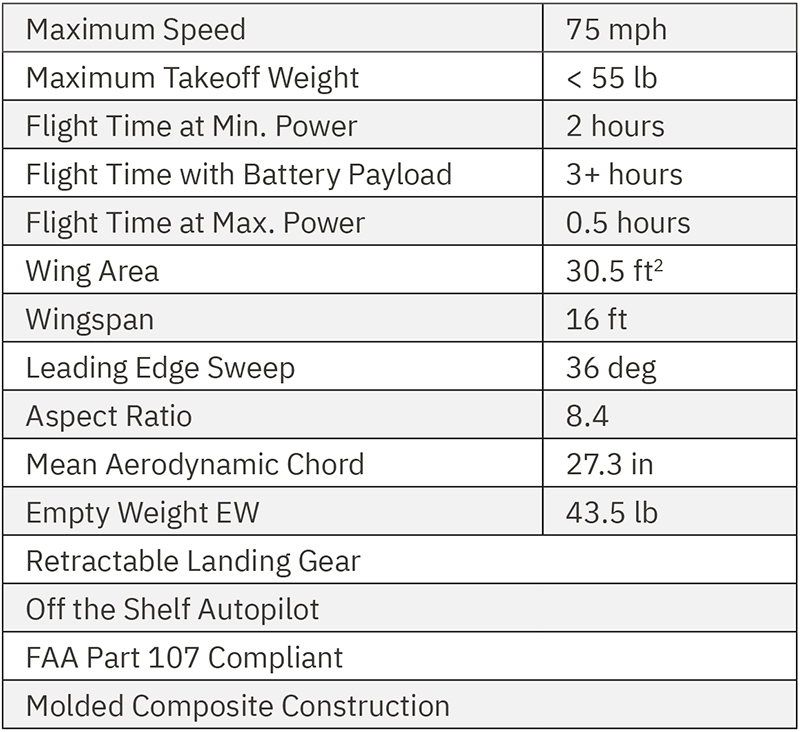

The XRAE-1 Foundation is more than a flying-wing UAV. It’s a technology demonstrator that showcases how quickly and cost-effectively Re:Build Answer Engineering can take a drone from concept to flight. Designed and built in-house, XRAE-1 Foundation represents the full potential of Re:Build Manufacturing’s integrated design, engineering, and manufacturing ecosystem.

Whether you need two units or two hundred, we can quickly scale to meet your program’s needs.

XRAE-1 Foundation went from concept to flight in just 4 months. By empowering a focused, multidisciplinary team with a fully equipped shop and agency to get work done, we streamlined every phase of the project from early requirements through final validation.

We intentionally selected a flying wing configuration as they are notoriously challenging to design and fly. That means more conventional drone architectures (multi-rotor, tilt-rotor, tube-launched, etc.) are well within our capabilities. If you have a unique vehicle requirement, we’re ready to design around it.

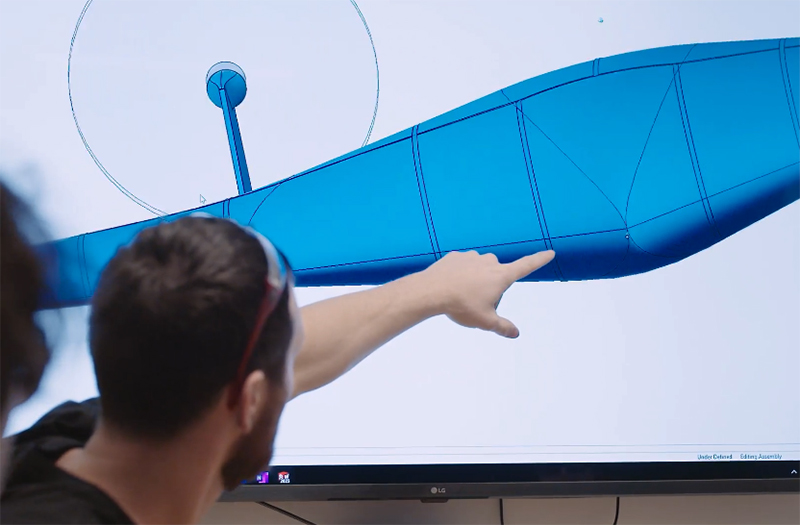

As part of this program, we developed proprietary software tool suites to optimize UAV configurations based on specific mission requirements and decrease time and effort needed in design.

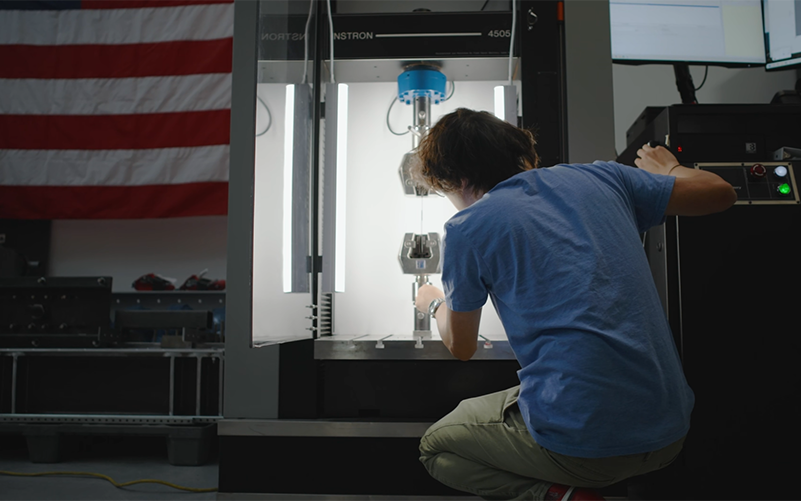

Our team blends advanced structural, aerodynamic, and control design capabilities with a hands-on, test-heavy approach. We use simulation and analysis tools to evaluate performance early, saving time by reducing design cycles.

Our prototyping process includes:

We don’t just design; we build, test, learn, and iterate.

We believe the future of drone manufacturing is domestic and scalable. The Re:Build Manufacturing ecosystem provides customers access to a wide range of cost-effective production capabilities.

From low-rate prototyping to full-rate production, our fellow member companies give us the flexibility to build the right supply chain for your program. Whether you’re launching limited quantities or preparing for volume production, we can tailor a solution that meets your technical and commercial needs.

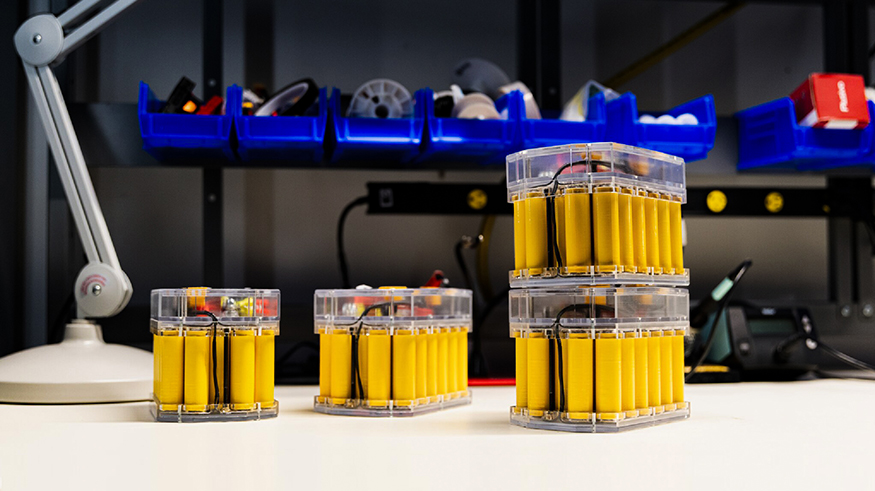

As we continue developing the XRAE-1 Foundation, future iterations will explore integrated energy solutions from within Re:Build Manufacturing. We specialize in battery pack and BMS design and development, supporting projects from early-stage concept through volume production with U.S.-based manufacturing.

These advanced capabilities in high-performance, scalable battery systems complement our UAV design approach, enabling tighter integration, improved efficiency, and rapid deployment of mission-specific power solutions.

Our validation process does not stop at software predictions. We perform coupon testing and full-scale structural tests to correlate and refine our analysis models. We run flight profiles to test motor and battery performance. We use flight simulators to preview controls and stability. This hands-on, closed-loop process gives our customers a valuable edge in catching problems early and building trust in the final product.

The XRAE-1 Foundation completed its first series of flight tests following ground testing. Conducted at a remote test site in central Colorado, the flights confirmed the vehicle’s aerodynamic stability, control responsiveness, and propulsion performance under real-world conditions.

Key objectives included verifying center of gravity and landing gear placement and validating the flight control system responses vs. flight simulator behavior. The aircraft performed as predicted, with all critical systems operating nominally.

The XRAE-1 Foundation airframe was engineered for efficient fabrication, structural integrity, and stable flight dynamics. This configuration balances simplicity and performance making it an ideal platform for demonstrating rapid UAV development.

The XRAE-1 Foundation validates our capabilities but is just the beginning to showcase what’s possible.

We want to help you prove out your platform. Whether you’re building a complex new vehicle or simply looking for a faster path to manufacturing, Re:Build Answer Engineering is ready to be your partner.

We have the tools. We have the team. And we have the resources to get it done fast.

Let’s get started.